Palletless handling

Slip Sheets replace wooden pallets

Palletless handling is primarily used in container transportation

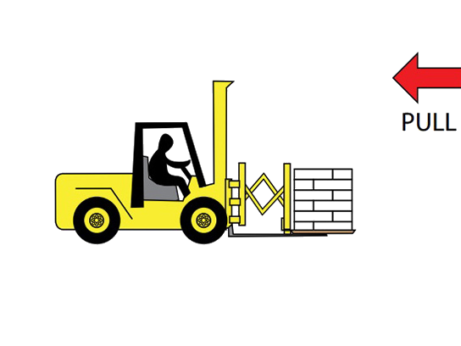

The main task of Palletless handling is as a replacement of wooden pallets with a less expensive, thinner, lighter and more environmentally friendly Slip Sheet. The goods are placed on the Slip Sheet, which is made of strengthened kraftliner or HDPE (High Density Polypropylene). The Slip Sheet is pushed or pulled by a special attachment called a Push-Pull, which can be easily added to any forklift truck.

How do you handle Slip Sheets?

The Slip Sheet is pushed or pulled by a special attachment called a Push-Pull, which can be easily added to any forklift truck. Push-Pull grips the Slip Sheet by the channeling, and so pulls the goods with the Slip Sheet under them onto stable forks, and moves it all to a container, where the goods and the slip sheet are quickly and easily loaded. Palletless handling can save on your employees’ energy expenditure, increase loading efficiency, and of course, most importantly, decrease your shipping costs.

Efficient used of container by Slip Sheets

Slip Sheets are thin, pallet sized sheets, which replaces wooden pallets. Slip Sheets are much thinner and lighter than a wooden pallet. Slip Sheets have a thickness of 0.6 – 0.8 mm, a wooden pallet has approx.15 cm. Slip Sheets have a weight of 620 gr/m2 whereas wooden pallets have a weight of 15 kg. You save 30 cm per m2 in a container and per load around 460 kg per container if you double stock pallet units in the container.