Thermal pallet covers

Thermal protection for pallet units

Sopack s.r.o. offers thermoregulation for pallet units

Thermal pallet protectors (pallet covers) are the most efficient and reliable solution for companies which export their goods and want to minimize temperature fluctuation. Thermal pallet protectors keeps a stable environment for pallet units during transportation by Air or Sea. These pallet covers are a great solution for mixed shipments or less than truckload carriers, when only some pallets must be protected against temperature changes.

Installation thermal covers

Thermoregulating cover with a velcro closure or classic zip has a simple installation. (Suitable from 150 cm and above). However, the risk of zippers is the deterioration of the thermoregulatory properties of the thermal packaging for pallet units.

Thermo cover with 1 Velcro Closure

Thermo cover without Velcro Closure

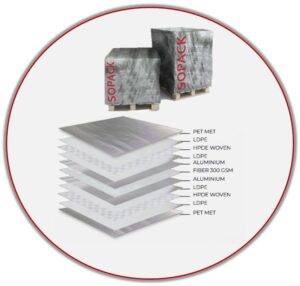

Thermo covers - Different materials

The Sopack company offers thermoregulating covers with a velcro closure or classic zipper for easy installation. (Suitable from 150 cm and above). We offer several suitable materials. Standard material ALU/Bubbles and ALU/LDPE/HDPE Woven/LDPE/PET MET. These materials are suitable for standard market needs. For higher demands, we offer other materials.

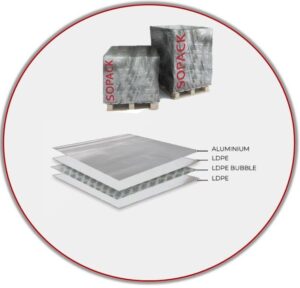

AP3 - ALU/LDPE/Bublinka/LDPE

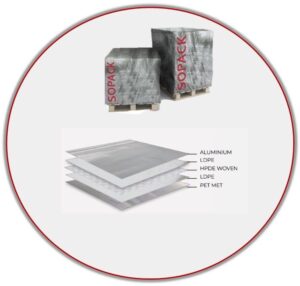

E130 - ALU/LDPE/Woven/LDPE/MET

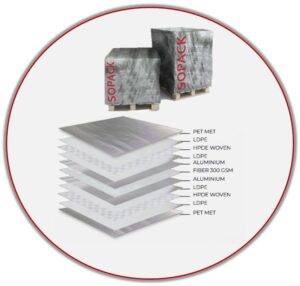

Speciální materiály

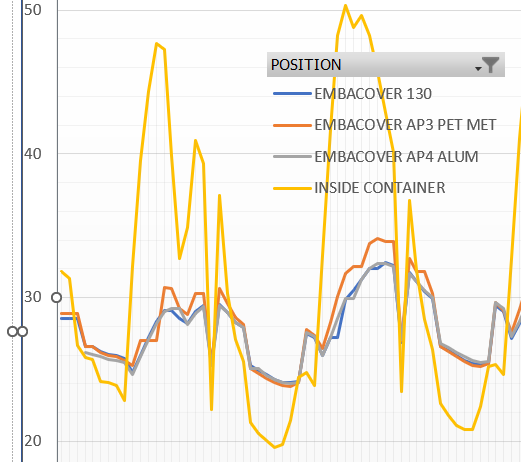

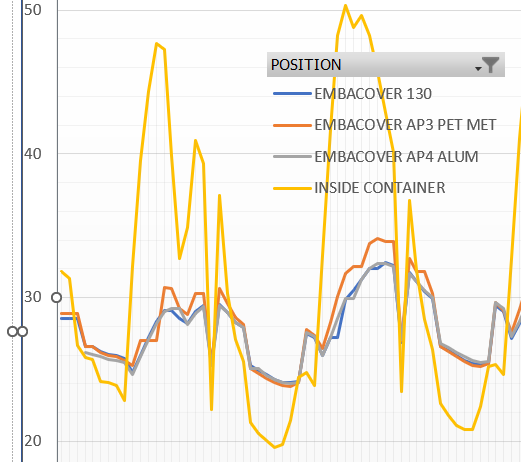

Comparison of materials E130, AP3, AP4

The graph shows the thermal insulation properties of the most used materials E130, AP3 and AP4. The E130 material wins the price/performance/durability/storability ratio. E130 material is ALU/LDPE/Woven/LDPE/MET.

Material E130

Insulating material used for thermal covers

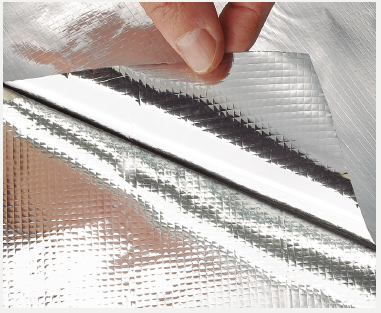

ALU/BUBLES/LDPE

Our composite material insulates the load. The thermo-regulating cover for the pallet is made of pure aluminum foil, which reflects heat (it is used, for example, in saunas). Bubble wrap, which has the task of thermoregulating goods and low-density polyethylene. The bubbles are filled with air, providing the insulation necessary to protect against temperature fluctuations. The composite thermoregulating and insulating material has a thickness of 3 mm. Thermal resistance is R=1.4 m2K/W.

Apperance

Material composition

- 1st layer: Aluminum foil

- 2nd layer of LDPE

- 3rd layer: Bubble wrap

- 4th layer: LDPE

- Basic specifications: Thermal resistance 1.4 m2K/W

Basic properties

Blocks radiation

Heat flow

7-10 years - lifespan

Reusable

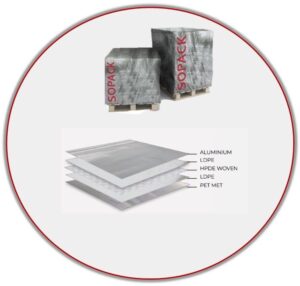

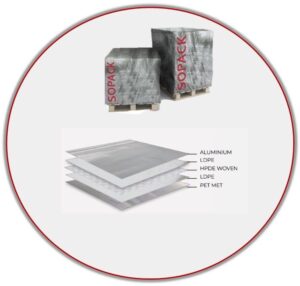

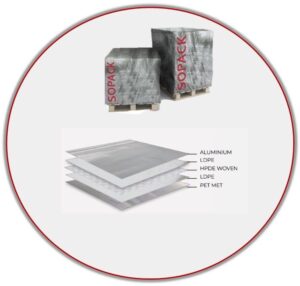

E130 - ALU/LDPE/Woven/LDPE/MET

Our E130 composite material insulates the load. The thermo-regulating cover for the pallet is made of pure aluminum foil, which reflects heat (it is used, for example, in saunas). Then ALU is laminated to Polywoven of HDPE and PET MET material. This composite material offers excellent insulating properties, equal to AP3 material. E130 thermal insulation material has two great advantages: consistency and higher tear resistance.

Material composition

- 1st layer: Aluminum foil

- 2nd layer: LDPE

- 3rd layer: HDPE Woven

- 4th layer: LDPE

- 5th layer: PET MET

Basic properties

Blocks radiation

Heat flow

7-10 years - lifespan

Reusable

Our recommendation

The thermoregulating cover for the pallet unit is made of two materials: ALU/BUB/LD serves for single and repeated use, and ALU/BUB/BUB/ALU provides even stronger insulation. Thermoregulating packaging for pallet units is designed to protect the goods on the pallet against temperature fluctuations. Our packaging has an excellent conductivity system, i.e. air flow around the pallet.

Founder of Sopack, Ing. Karel Sodomka